Special projects

We can run your entire project from start to finish

Our Special Projects Division was established to run your R&D projects right from the initial concept phase through to your final outcome.

At Sabre Tactical, we have a wealth of outdoor and military experience coupled with many years of manufacturing expertise all under one roof. This allows us to deliver excellence across the board and ensures that our products fulfil every aspect of your needs. Our custom-designed solutions and full range are manufactured with efficiency and reliability in mind.

Our process

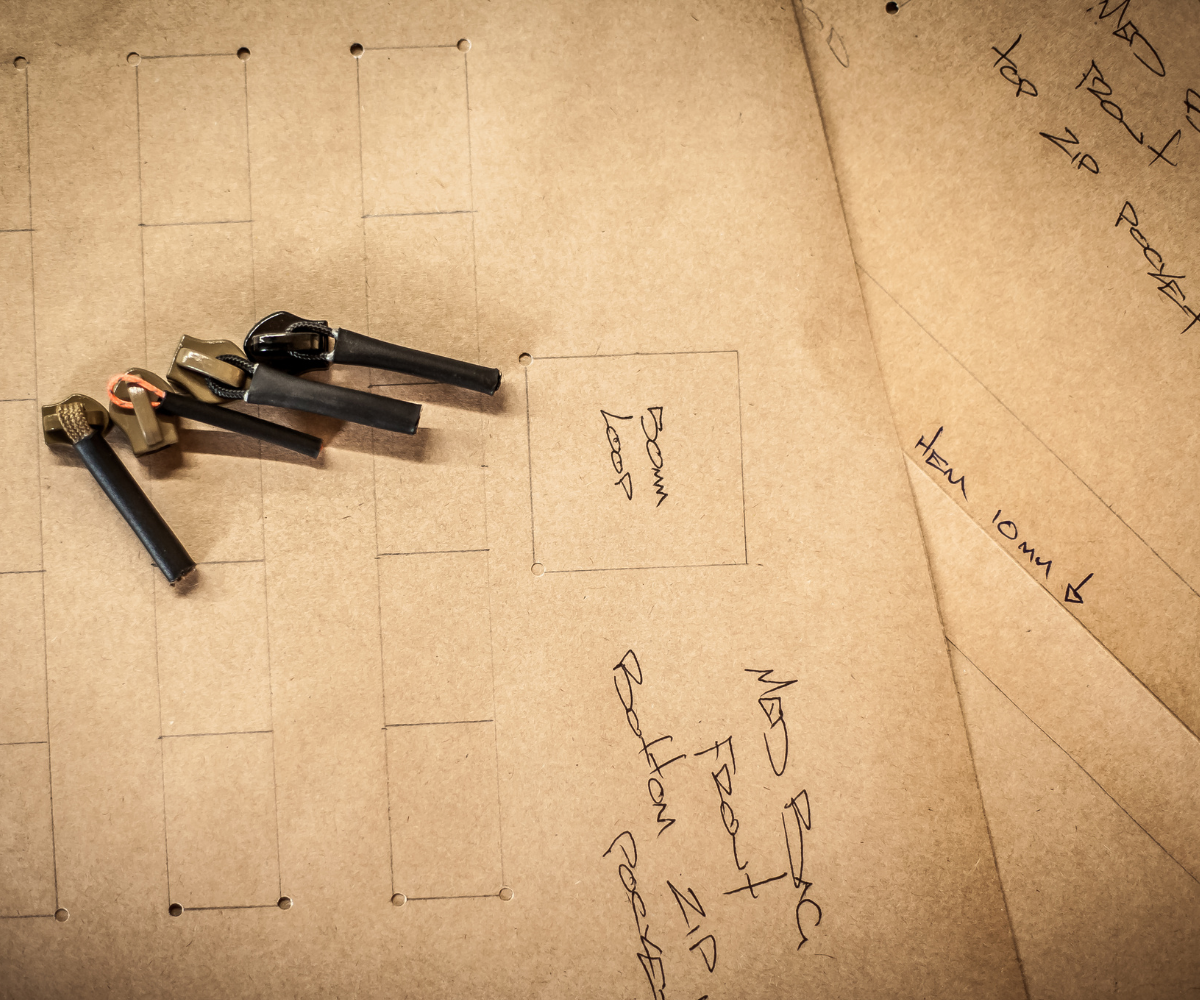

Concept

We combine critical thinking with thorough research and development, drawing on over a decade of experience in manufacturing, material expertise, and design techniques to create functional prototypes.

Detail

We offer more than just sewing; we work with Kydex, provide 3D printing services, and utilise CNC components to elevate your product. When needed, we collaborate with specialised subcontractors to create highly customised prototypes, ensuring your product is fit for purpose.

Prototype

Once we have a functional prototype, we don't simply hand it over. We conduct thorough testing, gather your client feedback, and make any necessary adjustments to ensure the final product fully meets the design intent and specifications.

Manufacture

Once your product is finalised, we eliminate the need for outsourcing. Our fully equipped in-house manufacturing facilities in Hamilton are capable of handling both small and large production runs.

Have a problem that needs to be solved?

Enquiries: info@sabretactical.co.nz

HAMILTON NEW ZEALAND

Visits by appointment only

The best products start with the best raw materials

Made in New Zealand

Innovation

Design

Craftsmanship